Essential Kegerator Coupler Parts for Your Home Brew Setup

Have you ever questioned why your draft pours either full of foam or completely flat? Those issues often trace back to the little parts that bridge your keg and tap. An improper setup can strip even premium brews of their carbonation and flavor.

Installation Parts Supply understands that flawless pours begin with reliable components. Whether you’re a homebrewing enthusiast or just love fresh draft beer, understanding these d system keg coupler pieces ensures every glass is served just right.

Whether it’s a washer or a length of gas tubing, each piece helps preserve carbonation and flavor. More than nine out of ten pour problems stem from mismatched or worn parts. Understanding these parts is the key to a trouble-free draft system.

Notable Observations

- Choosing the right coupler guarantees ideal flow and taste.

- Count on Installation Parts Supply for trusted draft setup parts.

- Regular maintenance prevents common pouring problems.

- Various brews call for particular coupler designs.

- Most system failures originate from coupler-related issues.

What Is a Kegerator Coupler?

A great pour all hinges on how your keg hooks up to the tap. A keg coupler bridges your CO₂ cylinder or nitrogen tank to the beer line, using compressed gas to push liquid smoothly to your taps. Think of it as the engine of your draft beer system—without it, nothing flows.

This small device has two jobs: it delivers gas to pressurize the keg and controls beer output. Within its housing is a probe, a check valve, plus dedicated gas and liquid ports. Each part ensures your brew stays carbonated and pours without foam.

| Part | Function | Frequent Problems |

|---|---|---|

| Probe | Punctures the keg seal | Misalignment causes leaks |

| Check Valve | Stops beer from flowing backward | Flat pours from worn seals |

| Gas and Beer Ports | Links to tubing | Loose fittings create foam |

Misconnecting the coupler is a common error—three out of four novices slip up. The result? Foamy messes, leaks, or worse, spoiled beer. Installation Parts Supply supplies charts and video tutorials to guide you.

Even “universal” styles need to correspond with your keg’s standards. The incorrect coupler not only spoils the beer, it can wreck your setup.

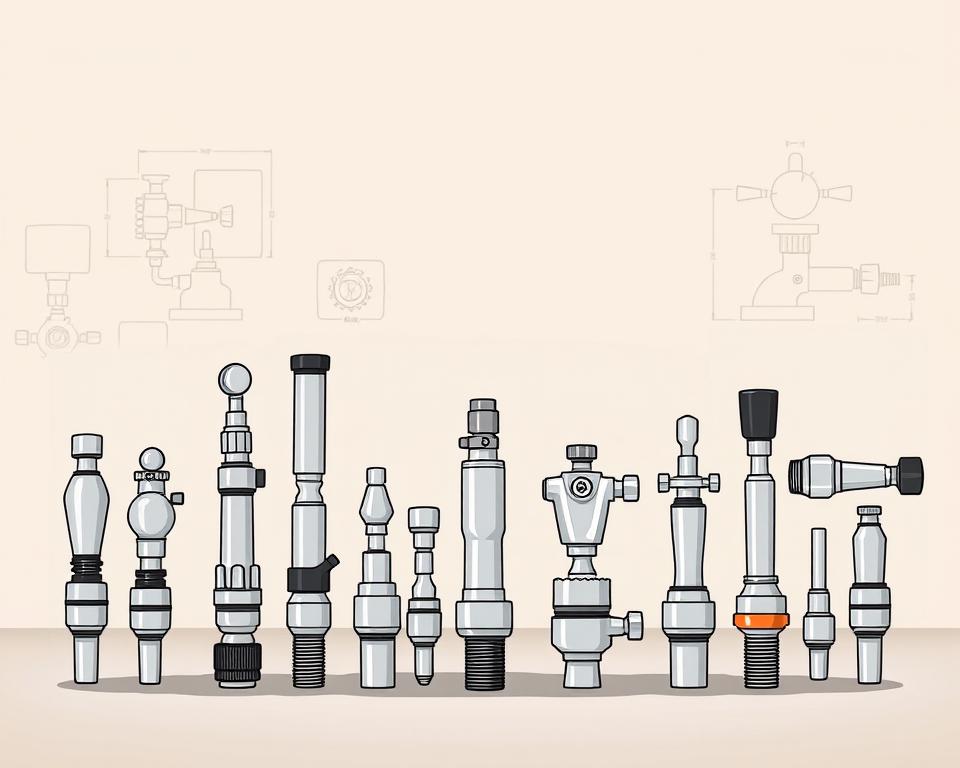

Keg Coupler Varieties and Applications

Not all keg connections are created equal—some are designed for specific brews. The correct coupler preserves carbonation and taste. Use these tips to select your coupler.

D System (Sankey) Coupler

Most North American brews—about 85%—use this style. Its single-valve design locks securely onto most domestic kegs. Tip: Check for “Sankey” etched into the coupler.

U System Coupler

Stamped with a harp mark, it’s essential for nitro-charged stouts. A 75% nitrogen mix gives you that signature creamy foam. Never force a U coupler onto a standard keg—it won’t seal.

Reverse-Thread S System Coupler

Heineken and other European imports need this reverse-thread version. The left-hand twist prevents mix-ups with D Systems. Fun fact: It’s slightly taller than its American cousin.

A-, G-, and M-Type Couplers

German and UK beers demand specialized connectors:

- A System: Slides onto Warsteiner or Paulaner kegs. That slider lock never slips.

- G System: Tri-flat stem locks onto Bass & Boddingtons. A pub staple across the UK.

- M System: Locks onto Schneider Weisse kegs. The slide-lock clicks when secure.

Their guide highlights D in green, U in black, S in blue. One Midwestern brewery cut costs by $3K annually with the right couplers. Remember: True compatibility beats “universal” claims every time.

Key Coupler Components Explained

Behind every smooth pour lies a set of precision-engineered components. Together, they keep carbonation in and foam out. Let’s break down the key hardware that keeps your system running.

Probe and Check Valve

A stainless probe punctures the seal to regulate flow. Quality probes endure three times as many uses. Underneath, the check valve stops reverse flow—our top replacement item.

Hex Nut and Washers

A tight seal starts with the hex nut. Brass is economical; stainless fights rust. Nitrile outperforms EPDM under 40°F.

| Part | Material | Key Benefit |

|---|---|---|

| Coupler Probe | SS | Long-lasting |

| Check Valve | FDA-approved plastic | Prevents flat beer |

| Hex Nut | Brass/Stainless | Cost-effective & durable |

Gas and Liquid Ports

Gas ports manage 20–30 PSI of CO₂ or nitrogen. Incorrect pressure spells foam issues. Use 3/16″ tubing for beer lines; 1/4″ causes extra agitation. Rebuild kits with FDA seals simplify maintenance.

Pro Tip: Swap O-rings every 6 months or 50 kegs. A $3 washer replacement beats a $150 coupler failure.

Setting Up Your Coupler

Getting your draft system right means perfect pours every time. Proper installation prevents foam, leaks, and flat beer. Use this step-by-step for a seamless install.

Mounting the Coupler

Open the handle, fit lugs into place. Twist until firm; don’t over-torque or harm the seal. Low-profile designs reduce height by 4–5 inches for tight spaces.

Our wrench sets hex nuts to the ideal 8-10 ft-lb. Eighty percent of leaks stem from a crooked probe. Never reuse old washers.

Line Connections

Hook the gas line on with 5/16″ fittings. Seal threads to stop CO₂ from escaping. Keep beer tubing 10-12′ of 3/16″ ID for best flow.

| Step | Equipment | Tip |

|---|---|---|

| Gas Line | Pipe dope | Check with 30 PSI leak test |

| Beer Line | Pipe cutter | Cut straight for proper seals |

| Leak Test | Leak detector | Check for 24 hours |

Advanced systems integrate mobile apps for real-time pressure monitoring. Our quick-connects helped a Denver bar slash foam by forty percent. Turn off gas immediately if you spot big leaks.

Common Coupler Problems & Fixes

A foam burst spoils your draft faster than anything. Once you know what to check, most issues are easy to fix. Let’s tackle the frequent headaches and their solutions.

Foam & Leak Fixes

Foam accounts for 68% of draft system complaints. Ensure your temp hovers around 38°F to control foam. Warm beer releases CO₂ prematurely.

Next, inspect your beer line connections. Soap test any fitting—bubbles point to leaks. Use a wrench to snug loose parts, avoiding over-torque.

- Check ball may hiss and interrupt flow

- Pressure imbalance? Compare your gauge to this chart:

| Beer Type | CO₂ Pressure | Nitrogen Mix |

|---|---|---|

| Pilsners | 10–12 | N/A |

| Nitro Stouts | 25–30 | 75% nitrogen |

Loose Coupler Issues

If your coupler fits loosely, first check for worn O-rings. Our data shows O-ring swaps resolve 40% of loose fits. If the face is warped, swap the entire coupler.

Use plastic shims to level off rough keg tops. A few dollars in shims cures tilt issues. Slim couplers fit into tighter kegerators.

Pro Tip: An emergency kit with five washers fixes most sudden leaks. One Chicago pub trimmed loss by 18% with staff training.

Tank icing means you need to ease off the gas. Allow the tank to warm up prior to any valve tweaks. Recalibrate digital gauges every year.

Coupler Cleaning & Care

A clean draft system means crisp, fresh-tasting beer every pour. Residue can dull taste and impede flow. A quick cleaning regimen prevents issues.

Disassembly and Soaking

First, disassemble the coupler. Separate the handle, probe, and check valve. Let the parts sit in warm PBW solution (1 oz/gallon) for 15–20 minutes. That will strip away yeast residue and hop buildup.

Installation Parts Supply’s brush set reaches tight spots. Pay extra attention to the ball valve—it’s a common hiding place for gunk. Flush well to prevent soap residue.

Choosing the Right Cleaning Solution

PBW (Powdered Brewery Wash) is a top pick for its pH balance. Acid cleaners work faster but can damage rubber over time. Sound-wave cleaners strip away stubborn grime.

- Air Drying: Use compressed air or microfiber cloths.

- Sanitizing: Follow FDA CFR 117 guidelines—30 seconds of contact time kills bacteria.

- Logs: Track cleanings with a template.

UV light options add extra protection for rubber components. Dispose of alkaline wash properly to protect drains. A quick clean routine preserves flavor and longevity.

In Closing

Savor every pour once you’ve perfected your draft setup. Correct parts, clean routine, and proper install equals perfect pints. Installation Parts Supply backs you with expert help and discount rebuild kits.

Regular upkeep can stretch your hardware lifespan by seven years. Download their free compatibility checklist or join a brewmaster webinar for pro tips. A quick annual inspection ensures trouble-free operation—just ask their 5-year satisfied customers.

Time to level up: head to Installation Parts Supply and improve your home bar.